Flexible, High-Temperature/High-Heat Thermoplastic Polymers and Compounds for Wire and Cable Applications

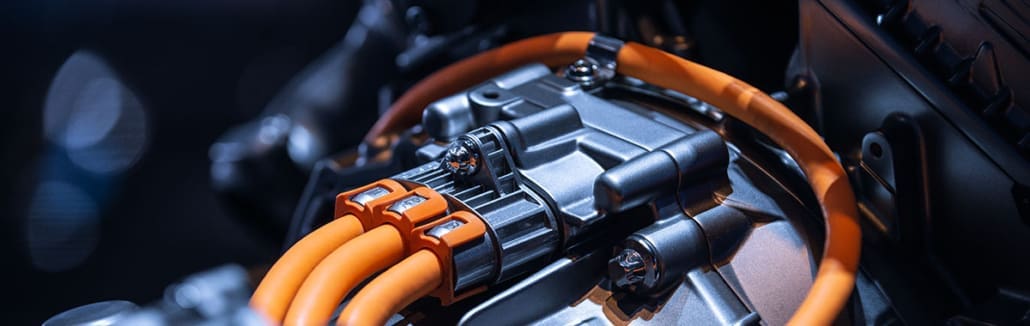

Engineered for High Temperatures, Formulated for Heat Resistance, Designed for Demanding Conditions Where Low-Smoke Zero Halogen & Flame Retardant Wire Insulation & Cable Jacketing is Required.

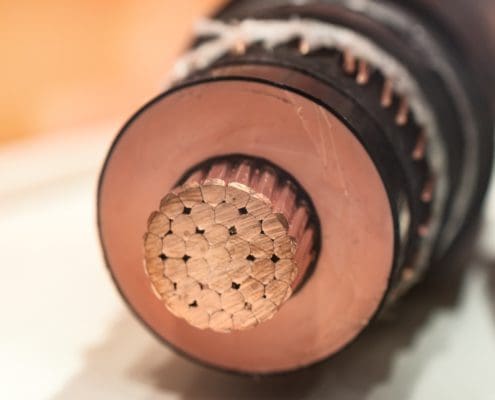

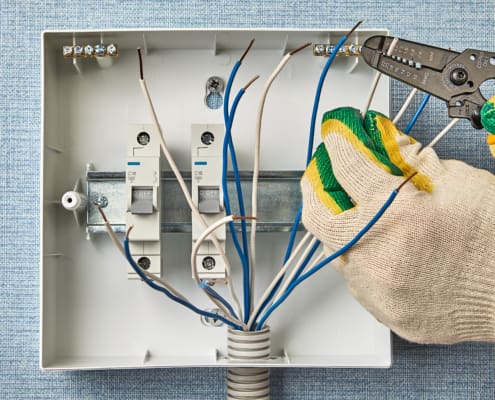

Aurora’s thermoplastic compounds and engineered polymers are purpose-built for the wire and cable industry; delivering the durability, flexibility, compliance, resistance to high temperatures, LSOH/flame retardant properties, and performance that today’s demanding applications require. Our solutions are tailored to meet our customers’ specific use cases across dozens of wire and cable types; including high speed data transmission, marine/shipboard cables, oilfield cables with the harshest of environments, and industrial machine cables needing the highest level of performance across the widest temperature ranges.

We formulate compounds that meet industry standards like UL, CSA, NEC, ICEA, IEEE, RoHS, and REACH, and support advanced cable manufacturing processes including extrusion, cross-linking and co-extrusion. Whether you need low-smoke zero-halogen (LSZH) jacketing, flexible insulation for tight-radius bends, or UV- and chemical-resistant compounds for outdoor or harsh environments; Aurora compounds and polymers are engineered for consistent performance and cost-effective scalability.